Vintage Air Creates New Pre-Treatment Process for Powder Coating

Share

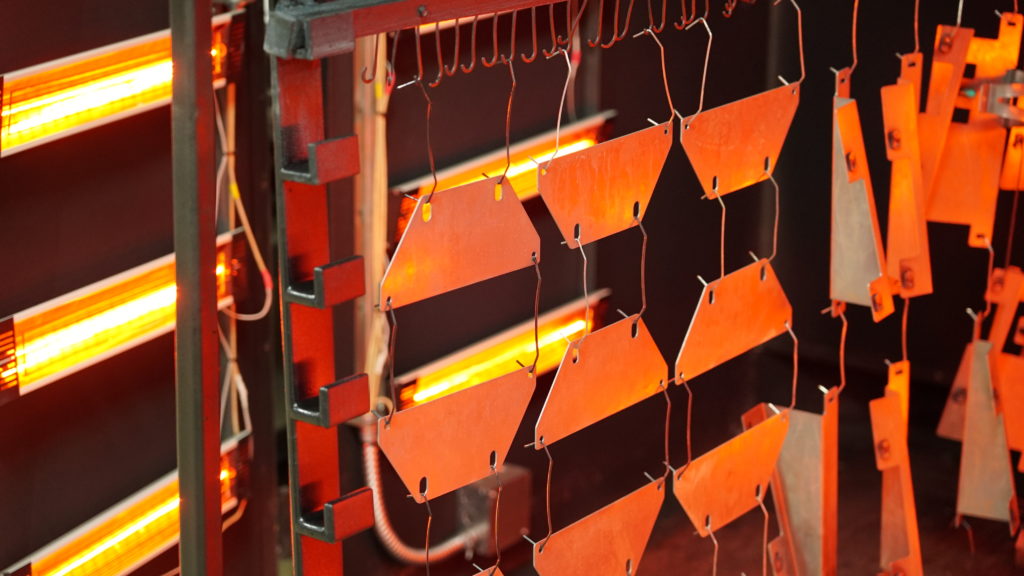

Vintage Air’s new pre-treatment process provides a longer lasting and more durable powder coating to ensure only the highest quality product makes it to consumers.

/wp:heading wp:paragraphVintage Air, the leading manufacturer of complete performance air conditioning systems for street rods, sport trucks and performance cars, has designed a new pre-treatment process for its in-house powder coating. The result is a far superior product than preceding finishes.

When looking for new ways to improve the finish on Vintage Air products, taking the powder coating process in-house was the first step. Rather than doing a quick wipe down in preparation for powder coating, putting the materials through an extensive pre-treatment process primes the raw surface for a smooth and sturdy finish. Hubbard-Hall, the leader in chemical products for surface finishes, was the first place we looked for help when designing the formula for the new pre-treatment solution.

The new process was created by Vintage Air’s manufacturing engineering team, led by Senior Chemical Process Engineer, Allison Chisenhall-Harding, who is also the daughter of owner and founder of the company, Jack Chisenhall.

/wp:paragraph wp:gallery {"ids":[2915,2916]}

Chisenhall-Harding integrated three of Hubbard-Hall’s advanced cleaning products to create the new process. “These off-the-shelf solutions resulted in substantial cost savings and quality improvements when compared to alternate pre-treatments we considered, such as other methods of chemical and mechanical processing,” Chisenhall-Harding said. The multi-step process dips the parts through each of the three chemicals before the powder coating is applied.

The new pre-treatment process helps the powder coating better adhere to the metal by stripping it of any contaminants that may interfere with the bonding process. This helps to achieve a more refined end result that is stronger and more durable.

/wp:paragraph